Metal Roof Flashing Corner Metal Roof Flashing Manufacturer from Jaipur

Oatey® invented the flashing industry more than 100 years ago. Today Oatey Flashings are used in commercial and residential applications where a water-tight seal around plumbing vent pipe or outside wall penetrations is required.

How To Install Roof To Wall Flashing boostbad

Roof Materials Expenses Associated with Flashing Installations and Repairs. The national average cost to hire a roofer to replace the flashing, shingles, and to seal a leak in a small area of the roof is between $300 and $1,100. Larger roof fixes can cost between $1,100 and $1,500+. New Shingle Roof.

Roofing Custom Metal Flashing TorontoRoofing.ca

Begin pre-drilling your screw holes. At the edge of the top section of trim, pre-drill a hole 1" inside and 2" from the edge on both sides of the trim. If overlaps are needed, don't put a screw in the last 12" until overlap is done. Prior to fastening the pitch break trim, place silicone sealant on top of the foam closures.

Roof Flashing Protects Against Water Infiltration Hunker

Learn How To Install Metal Roofing Flashing. Eave Trim And Drip Edge Installation On A Metal Roof. STEP BY STEP INSTRUCTIONS for installation of drip edge an.

Example Residence “B”

Firstly, thoroughly cleanse the metal roof surface where the flashing will be added. Remember, water and debris can impede correct installation, affecting the final result. Keep in mind, flashing is a critical component of roofing, especially for metal roofs, as it protects your home from water intrusion. Following a guide can help ensure a.

VELUX Skylight Flashing Systems for roofs Deck and Curb

Apply Sealant and Butyl Tape. To ensure a watertight seal when flashing a metal roof to a wall, start by applying a silicone sealant along the edges where the roof meets the wall. Next, use butyl tape, a waterproof adhesive tape, on the backside of the metal flashing for added protection. This will create a tight seal against water intrusion.

What is Roof Flashing?

Step By Step Endwall Flashing Installation Instructions On A Metal Roof. Install Metal Roof Endwall Trim At The Sidewall. Installation Instructions For Endwa.

Sheet Metal Flashing At Precast Wall On Flat Roof In Etobicoke Metro Images and Photos finder

Screw it down in a way that its fits tight over the humps of the metal roof. Use your feet to flatten the flashing down over the contour of the roof. After screwing it down securely, do another bead of silicone around the edge also put some silicone on all the screws as well. Use your finger or a tool to smooth the silicone around.

Metal Roof Metal Roof Flashing Details

Roof Flashing & Purlins. Metal Flashing; Metal Flashing. Sort By. All Filters. Compare. CAgroup 100mm x 10m Weatherproof Byute Flash Flashing Tape (11) $46.89. Add to Cart. Compare. CAgroup 150 x 0.3mm x 10m Weatherflash (0) $20.52. Add to Cart. Compare. CAgroup 50mm x 10m Weatherproof Byute Flash Flashing Tape

Roofing and Flashing Tips DIY

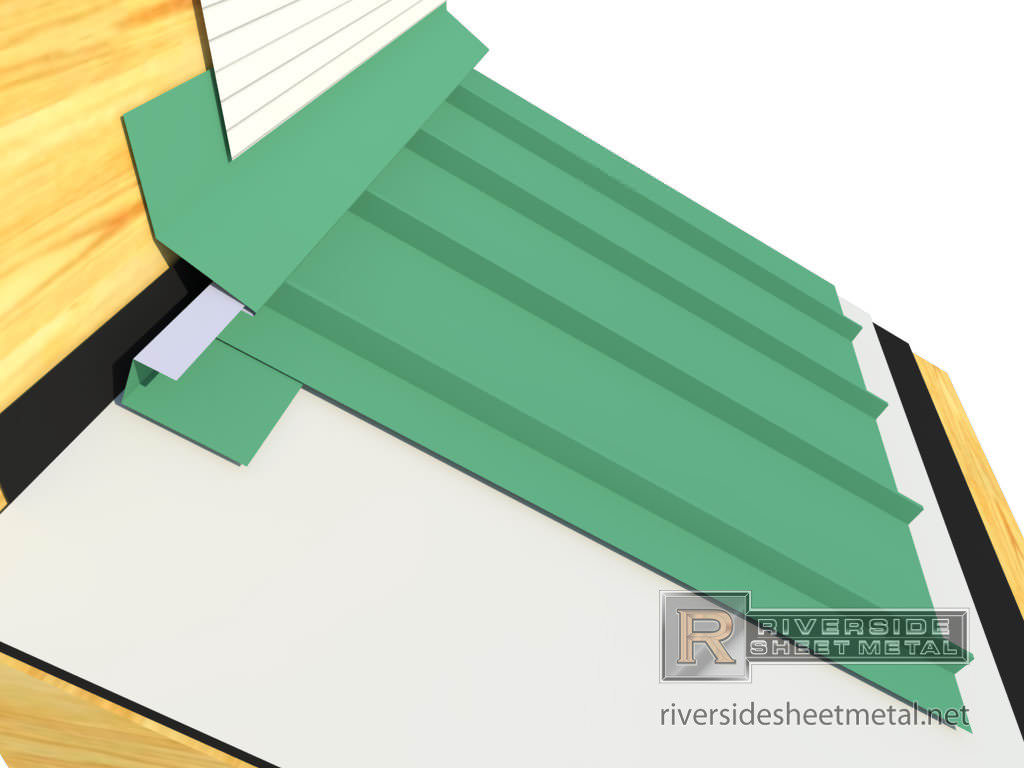

Step 3: The Installation Process. Here are the steps for installing metal roof flashing. Begin by securing the base flashing, creating a stable foundation. Add step flashing around walls and valley flashing along intersections. Each layer contributes to a seamless flow of water, creating a waterproof roofing system.

Pin on Gabled end

Learn how to install pipe flashing and vent pipe flashing on a metal roof. EASY STEP BY STEP Installation directions to install rubber pipe boot on corrugate.

Roofing Custom Metal Flashing TorontoRoofing.ca

Mark your trim on the hem side 6" from the end and ⅛" up from the hem. With metal cutting snips, notch out the hem of the endwall by cutting along the traced line. On the adjacent piece, pry open the hem of the endwall by 6" to allow it to slide into the notched piece. Place silicone sealant at all overlaps.

Metal Roof Flashing YouTube

This video describes different techniques for installing edge flashing for metal roofing. In it, I'll show you how to apply drip edge and rake flashing.Go to.

What Are Roof Flashings and How are They Used? Western Pacific

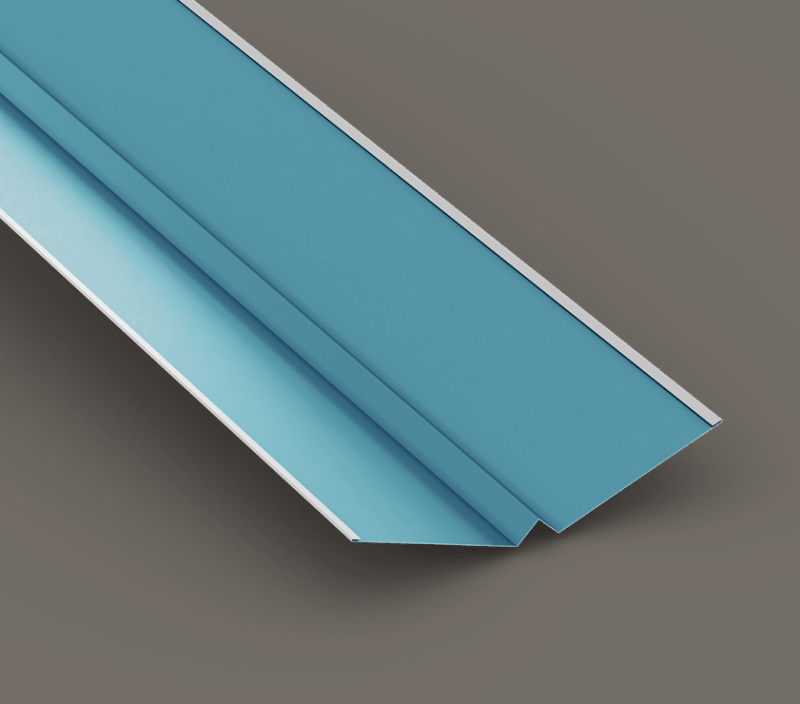

Tolerances. Stramit® Flashing, whether standard or special, is manufactured to the same high standards and tolerances.Although normally produced within these values, assume the following tolerances when detailing flashing: fold to fold and fold to edge distances +/- 2mm. overall length +/- 15mm. bend angles +/- 2°.

Roof Ventilation / Flashing American Standard Roofing

A professional metal roofing installer will have the experience to know which fasteners are best suited to provide reliable, long-lasting protection. Ongoing Maintenance of Metal Roof Flashings. Regular maintenance of your metal roof flashings is crucial to their long-term performance. Some key maintenance tips include: 1.

Roof Valley Flashing GEIT Metal Roof Accessories Factory

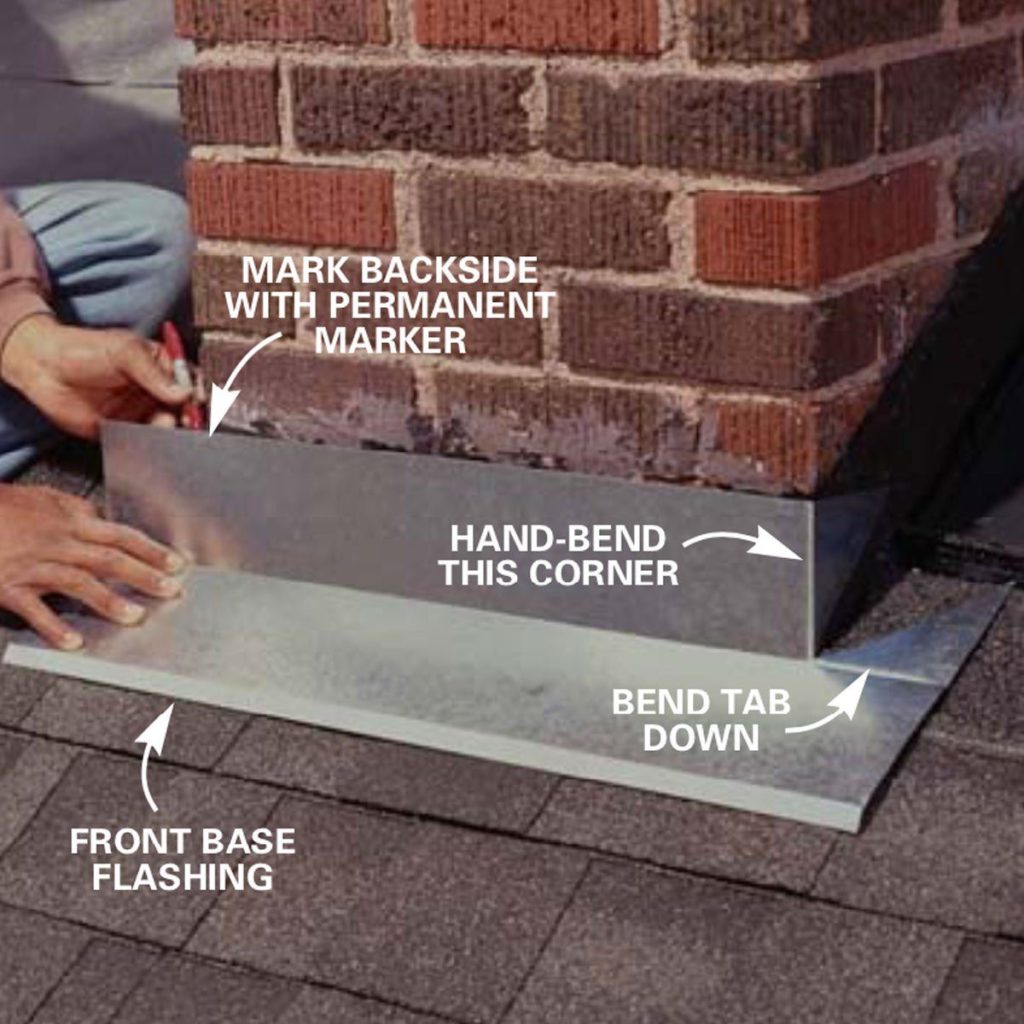

5. Push the metal around the corner or edge to form a 90-degree bend. Press 1 palm firmly against the metal where it sits against the surface to hold it steady. Use your other hand to push the other side of the metal all the way around the corner until it's bent at a 90-degree angle down the middle.